Automation System

With our unique technology and competitiveness,

we provide products that fit just like tailor-made clothes.

YMP creating the best value through advanced technology

Quality stabilization and zero defects through continuous single PPM activities Single PPM in progress under the vision of “Leap to a high-quality, zero-defect company”

Single

PPM

- Improvement

Activities - TPM

Activities - Quality/Environment

System

- Quality

Innovation - Perfect

Quality - Customer

Satisfaction

-

1

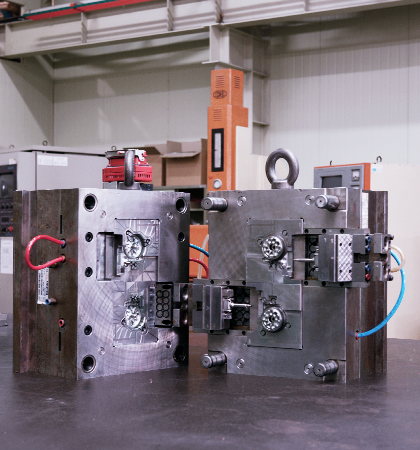

Mold design

High hardness mold material processing technology and mold design technology employing hot runner

- Technology for short-time processing of mold materials with increased hardness after heat treatment

- Mold design technology that employs a hot runner that satisfies the optimal molding conditions

Applied Effect

- Produced over 1 million shots with high hardness molds

- Reduce incidental cost and improve quality by applying hot runner

- Able to set molding conditions and improve quality such as product deformation and dimensional stability

-

2

Raw material supply

Centralized automatic raw material feeder

- Central supply device that supplies and dries raw materials supplied to the injection machine and automatically feeds them

Applied Effect

- Reduction of raw material replacement time

- Cost reduction with automatic raw material supply system (reduction of manpower, improvement of productivity)

- Quality Equalization

-

3

Molding injection machine (electric type)

Electric dispensing machine adoption

- Realization of high-speed injection and precision injection by controlling the sub-motor of the electric injection machine

Applied Effect

- High-speed precision injection improves product precision

- Productivity improvement and defect reduction

- Improvement of cost competitiveness

-

4

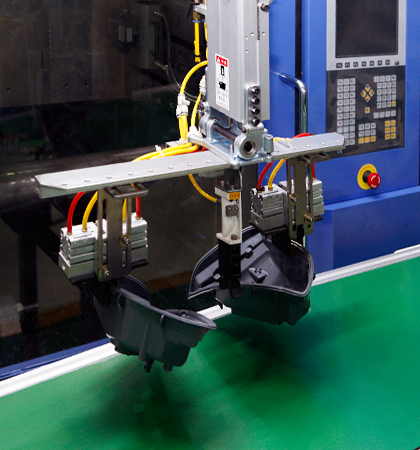

Automatic product take-out

Automatically take out molded products with a robot

- Improved productivity by automatically taking out molded products with a robot

Applied Effect

- Cycle Time Savings

- Increase productivity and strengthen competitiveness

-

5

Hood Latch Release Assembly Machine

Electric Hood Latch Release Assembly Machine

Applied Effect

- Increase productivity and strengthen competitiveness